DFG Major Instrumentation Initiatives – machine for DED-LB/M research approved

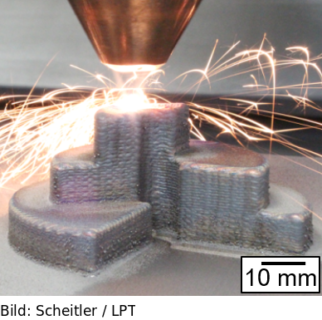

As part of the Major Instrumentation Initiatives by the German Research Foundation (DFG) the Institute of Photonic Technologies at FAU Erlangen-Nuremberg was granted funding for a Direct Energy Deposition (DED-LB/M) machine. The submitted concept surpasses commercially available system technology with its integrated process monitoring capabilities as well as the transferability to large-volume components.

This machine will allow to build on the institutes research in the field of difficult-to-weld materials as well as composite materials successfully carried out since 2013. Furthermore it will enable research on high-throughput in-situ alloying using several powder materials, aiming to tailor material properties within the production process.

Key features of the DED-LB/M machine are:

- Flexible processing based on a 5-axis module with integrated single-mode fiber laser system

- Beam profile modulation based on the principle of Coherent Beam Combining (dynamically with up to 50 MHz)

- Powder feeding unit with four hoppers and fast powder switchers

- Integrated process monitoring based on a two-color pyrometer and an IR camera

- Automatable cleaning and downstream chemical composition analysis of specimen using LIBS

Dynamic beam shaping provides new degrees of freedom in process control by adjusting the cooling rates and thus the process dynamics. This will be adopted to study the possibilities of in-process material property adjustments. Another goal is to increase process stability and efficiency (e.g. powder utilization). The combination of several powder feed systems, fast powder switchers together with the monitoring of the respective powder streams allows to adjust the chemical composition without significant delay during production, which is required for detailed studies on in-situ alloying. To minimize deviations in the outcome of the DED machining, data from the integrated process monitoring will be provided to the control unit of the machine.

Further information (German): DFG, idw. (12.03.21)